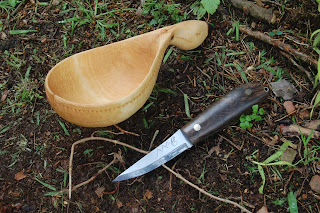

The MaChris Bushcraft and carving knife.

Designed by : Jon Mac.

Crafted by : Chris Grant.

This MaChris has been in Research and Development for approximately three years.

Chris Grant and I have been working closely together to design and make the best possible knife for carving and camp work.

I believe we have it in the bag.

The MaChris Bushcrafter is a full tang knife, and is made using 52100 bearing steel.

This steel is very tough and will not fold or chip in even the hardest of woods.

The cutting edge can be kept razor sharp using a good water stone 6000 grit or above, and a light strop on leather with high quality compound.

The MaChris has a Scandinavian grind, ideal for carving and skinning.

The fine tip allows for the working of tight internal radii curves.

The MaChris handle is of a fine ergonomic design that allows for long periods of use without fatigue or blistering.

The handle is designed to give a high degree of comfort and deliver maximum power in forward and reverse grips.

The design also allows for stable holds with just the small and ring fingers thus allowing a safe grip right at the fine tip of the blade, great for fine carving or skinning.

The overall length of the the MaChris is 8 3/4 inches.

The blade length is 4 inches.

The width at the spine is 1/8 inch.

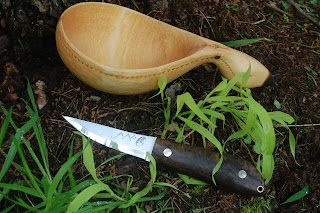

The MaChris has a smaller brother we call the MiniMaC.

The MiniMaC is a scaled down version and designed for smaller carving work.

An ideal carver with a very comfortable ergonomic handle design.

The blade has a pin tang and is again made from 52100 bearing steel.

The fine tip allows for the carving of tight internal radii curves. And the tip is also fine enough for good quality chip carving.

The overall length is 7 3/4 inches.

Blade length is 3 1/4 inches.

And width at spine is just a smidge over 1/16 inch.

Here is a description of the development written by Chris Grant.

Angus.

Scotland.

November 2012

Well, I'm crashing Jon's blog. I hope the following's of interest.

I first encountered Jon Mac in 2009. I'd seen Jon's work and asked him what knife he used, we conversed about axes and Japanese laminated steel and it became clear Jon was interested in pursuing high(er) performance tools for his work, perhaps bespoke.

Jon had a few brand knives which he was very generous about, as well as his 'own knife', a multi layered stacked handle with a laminated blade hand forged by Julius Pettersen.

Of all the things Jon and I talked about, it always got back to this knife, it was admittedly not perfect, but it just worked for Jon, so we had our starting point.

Jon sent me up this knife, (call it a prototype for reference) while the handle was against my preferences at the time, I decided to leave it be as Jon was confident in it.

The blade was well made but lacked finesse, I reshaped it more in line with a template that Jon had sent me, in addition to this I tapered the point.

Immediately after this I set about making what would become the first version of the knife, the MaChris No1, A similar knife to Jon's Petterson, but built for purpose.

To be sure the handle was exactly right, I asked Jon to carve it (got me off the hook). I prepared a blade from 15N20 band-saw steel, chosen because of its keen edge and similarity to the steels Jon was used to using/sharpening.

My main contributions to the MaChris design have been the tapered point on the original knives (and later the MiniMac), as soon as I mentioned this Jon was dead keen, he loves the fine point for delicate chip carving and we retained that feature on the small MiniMac knife.

I also added a reversed 'thumb ramp' to the back of the blade, the spine scallops from the straight back of the blade to the handle, meeting in a smooth transition. Jon was very happy with this design choice and the comfort it offered.

The No1 was a success, Jon loved the knife and I was delighted that it worked for him.

Job done?

No!!

Jon came to visit me in September 2010 and while out in the woods I mentioned making a `full tang knife for him`, based on his design, Jon said `No. I don`t want any blisters`

So... I had to prove him wrong..

I sneakily made a full tang version of the knife from CS80 steel with birds eye maple slabs, and sent it down with another blade in silver steel.

The latter quickly became the top performer, even though Jon was initially suspicious of it... I also made another in O1 (which Jon did not think much of!)

Much to my delight and surprise Jon loved the full tang knife and it soon became his favourite for everyday tasks and for most carving, I was surprised, vindicated and motivated to keep going with this knife.

Months later I got some fabulous feedback about the knives and their various steel performances from Jon. He has been a fabulous resource of testing the edge retention and edge strength of different blade steels. His research and testing feedback independently and exactly matched mine!

Jon dearly loved the 15N20 and the CS80 knives, but they rolled on hard woods, the O1 fared ok, but Jon never got the fine edge he desired and was not particularly impressed with the edge retention.

With a few modifications, the silver steel MaChris became Jon`s go-to carving knife, it kept the sharpest edge for the longest time, again he was won over!

Later on I found a source of 52100 ball bearing steel. I had used bearing steel for tools before and used some continental tools made from them and was very impressed.

I was very excited to be able to use it, especially for this project.

Bearing steel is a relatively simple steel it's alloy allows for a very fine edge which is very strong and tough, often the two don't go together... to my mind it is perfect for woodcarving.

I made Jon a small knife blade from the bearing steel and he was delighted, it even outperformed the silver steel... another step forward!!

After a discussion with woodcarver friends Patti Landman and Sean Hellman amongst others, Jon decided a smaller, dedicated precision carving knife was needed.

He worked with me to make a smaller (slojd type) version of the MaChris, Jon had a very strong idea of the handle proportions (as usual) and the blade shape was to be the same, but smaller and with a tapered point like the No.1 prototypes.

He called it 'The MiniMac'

As of this Autumn, 2012, I have (finally) delivered the final versions of the MaChris Knives to Jon Mac, he has the Final versiosn of the full Tang MaChris and the MiniMac in 1/8" thick 52100 steel, I harden them to HRC 59 +/-1.

I am pleased to say Jon is happy with both!!

We are now totally happy with the final versions of the knives.

It's been a lot of fun!!

We learned a lot.

I hope you like the knives.

Chris Grant

Knifemaker

Please feel free to email me with any questions regarding the Machris knives.

My email is:-

firststeps@thewood.eclipse.co.uk

For orders please contact Chris Grant.

His contact details can be found at :-

Top Left: SFK, Bottom Left CUB design by Sean Mulhall © 2013

Top Right: MaChris Bushcraft Carver Bottom Right: MiniMac Carver Design by Jon Mac © 2013

Chris Grant Bladesmith

MaChris and MiniMac.

MiniMac.

If you would like to order a MaChris or MiniMac

please feel free to contact Chris Grant through his web page.

Makemethischris...

or drop me a line at

firststeps@thewood.eclipse.co.uk

Enjoy.... J